Our coatings are formulated specifically for high-impact and abrasion resistance at the most competitive prices.

Coatings applied by Alternative Surfaces can be easily and economically maintained and re-coated.

Our applicators use the most professional equipment and procedures to assure speed and simplicity of application. Our advanced equipment is custom manufactured for high production, top quality preparation methods for any and all types of floor conditions. Alternative Surfaces provides concrete sealing, hardening, densification, and water proofing services.

Despite its durability, concrete is a porous material, which means it can absorb water, chlorides, stains, and other water and oil base materials that it comes in contact with.

By treating the concrete with a sealer, you can inhibit the penetration of these intruders while allowing the surface to breathe, so moisture within the concrete doesn’t become trapped. Concrete is typically sealed with either a penetrating densifying sealer or a film forming sealer.

Penetrating water-base sodium silicate solutions harden and densify concrete by chemically reacting with the calcium salts present in concrete. It can be applied in one coat or multiple coats depending on the concrete porosity and can be used on either new or existing concrete floor. Sealers actually penetrate into the concrete surface to a depth of about 1 to 4 mills to increase water repellency and resist stains on absorbent concrete.

They provide invisible protection without changing the surface appearance, and can increase the surface strength of your concrete floor. Film forming solvent and water based acrylic sealers inhibit penetration of water and contaminants such as oil, grease, and stain by forming a barrier on the concrete surface. When used on newly placed concrete, sealers can help protect against spalling, dusting, efflorescence, freeze-thaw damage, and alkali degradation. Many also impart a gloss or sheen, so they often are used to enhanced colored, stamped, or exposed aggregate concrete.

Concrete always had the great advantage of being really tough, and the great disadvantage of being really grey, and gritty, and ugly.

Transforming concrete into incredible floors—and turning your project into a unique showcase—takes product and industry know-how, product excellence and client partnership.

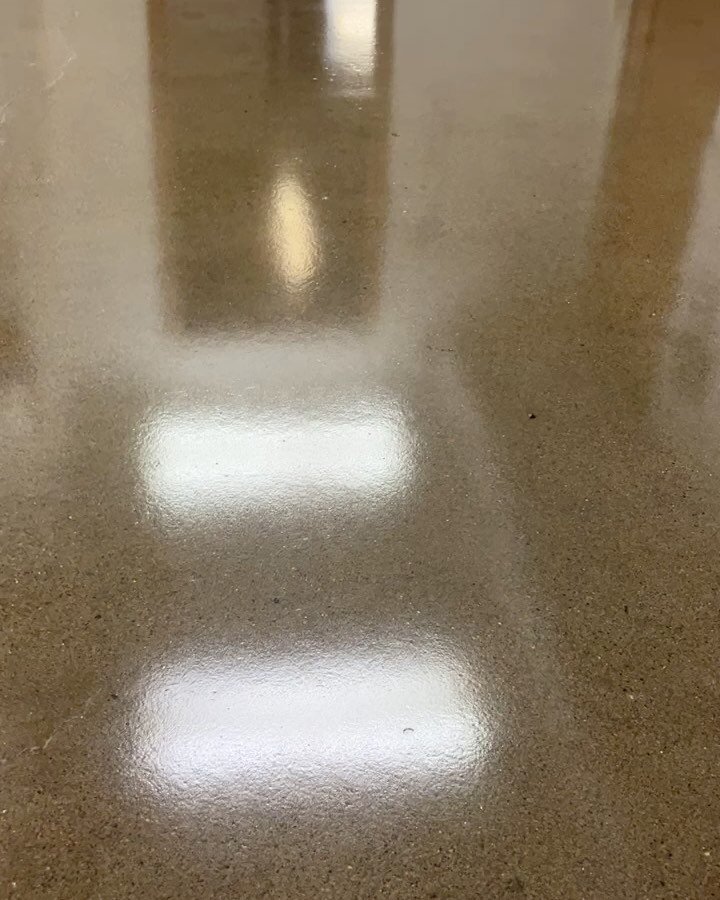

Alternative Surfaces, recognized for delivering product and project excellence, provides mechanically polished concrete flooring solutions to lend a design and performance edge to your project.

Moving away from short-term, high maintenance solutions such as epoxy coatings and thin film coatings, Alternative Surfaces delivers high-performing, low maintenance, long-term and cost-viable alternatives in its polished concrete offerings.

With state of the art, dustless concrete grinding equipment and expertly trained concrete specialists, we are equipped to provide professional, creative, project specific, customer focused solutions to help fashion floors and get it right for you from the ground up. We are committed to delivering excellence and leading edge solutions, for cost-effective, environmentally-conscious and high-longevity, low maintenance flooring.

“It was a pleasure working with you and your staff. Confidently and without reservation I recommend Alternative Surfaces.”

EPOXY COATINGS & POLISHED CONCRETE

Coatings applied by Alternative Surfaces can be easily and economically maintained and re-coated. Our applicators use the most professional equipment and procedures to assure speed and simplicity of application.

Alternative Surfaces’ Unique Processes

High performance floor coating

Alternative Surfaces Polyurea garage floors are the choice of homeowners and commercial contractors who want an attractive, long lasting and durable garage floor protection. The reason why polyurea flooring is applied is to protect the concrete from wearing off, from oil, grease, vehicles, foot traffic, animal urine etc. Alternative Surfaces garage floor have an advantage over modular flooring systems because our coatings becomes part of the concrete. Modular floors sit above the concrete and are subject to the moisture, dirt, grease and oil that may seep through it allowing mildew and stains to form below the tiling.

Epoxy concrete floor coating

Alternative Surfaces provides turn-key epoxy resin floor installation services, including removal of your existing floor system, surface preparation, and installation of the proper coating system for your industry. Our coating systems are designed to provide aesthetic enhancement and abrasion and chemical resistance to a floor surface. Because a coating is dense, seamless and has low porosity, it is easier to clean and maintain than an uncoated surface. Coatings are available in variety of colors, allowing you to match your floor’s new look to the rest of the environment. Alternative Surfaces offers thin-film and high-build coating systems for high end resistances, assembly and light manufacturing areas, aircraft hangars, food process areas, laboratories, clean rooms, pedestrian walkways, warehouses and similar industrial and commercial areas.

Urethane Concrete Floor Coating

Alternative Surfaces installs urethane floor coating systems to provide a very durable, easily colored, high gloss light reflective surface in demanding commercial and industrial settings. Like epoxy coatings, urethanes are available in a variety of options. One component versions are popular, ranging from 40 % to 100 % solids. One component products are called “moisture cured urethanes” (MCU) and are typically solvent borne. Water based urethanes are recognized for outstanding adhesion properties, while offering less durability than their solvent borne counterparts. An installation consisting of epoxy primer and two coats of moisture cure urethane remains one of the industry’s best values. In areas such as aircraft hangars, production areas, chemical processing plants, battery charging areas, and warehouses, “chemical resistance urethanes” (CRU) offer excellent chemical resistance to hydrochloric (muratic) acid, phosphoric acid, sulfuric (battery) acid, brake fluid, skydrol, jet fuels, and other industrial chemicals. CRU’s are cycloaliphatic in nature, reducing their tendency to yellow from ultraviolet light.

Alternative Surfaces offers a wide range of additional performance applications suitable for food and drug manufacturing, dairy plants, sensitive electronic equipment manufacturing, storage facilities, and more!

Epoxy vapor barrier systems for moisture control

Troweled epoxy mortar overlays

Flexible epoxy membrane systems

Urethane/ concrete troweled systems (FasTop or U-Crete)

NovoLac chemical and acid resistant corrosion control coatings

Malleable troweled epoxy mortar using metallic aggregate

Aircraft manufacturers and hangars

Automotive dealer showrooms and service areas

Automotive plants and assembly areas

Chemical plants

Clean rooms

Correctional facilities

Electronics manufacturing and computer areas

Food and dairy plants

Gaming facilities

Hospitals

Laboratories

Military base & storage facilities

Pharmaceutical production and storage areas

Restrooms, shower and locker rooms

Retail stores & outlets